Temperature Stabilized FT1000MP REF oscillator

In March of 2003 I checked the frequency of the REF oscillator in my FT1000MP using the process described in the note, “Checking and Setting the FT1000MP REF oscillator” on my web page. I found that not only was the REF oscillator frequency off after an hour using the radio, but that there was still a small amount of frequency drift after more than two hours of on time. After some discussion with Lyle, KØLR, I decided to install a positive temperature coefficient thermistor attached to the crystal can and see if that would not improve the stability.

The

REF oscillator board has a regulated +9 volt line which supplies the power to

the REF oscillator. (See schematic at end of this note). I followed the +9 volts back to the

regulator and estimated the amount of current that was being drawn from the

regulator by the various circuits that it feed. It looked to me as though I

could draw a constant 50 milliamps without any problem and probably could draw

as much as 90 milliamps at startup without a problem.

I

selected a 25 volt, 50 ohm (cold) thermistor [Mouser part number

527-3006-25v50/50C] for the variable resistance. Using a proto board I checked

the current drain for various resistors in series with the thermistor. A 68 ohm

resistor limited the startup current and allowed the thermistor to heat

sufficiently so that I could just feel that it was warm to the touch when

squeezed between my thumb and forefinger. At ‘full heat’ the current drain was

about 40 milliamps.

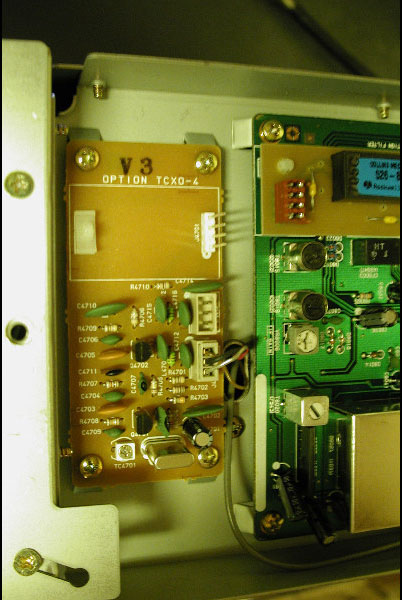

Figure 1

To

make the modification one must remove the REF oscillator board from the radio.

Remove the top and bottom covers and locate the board on the right front side

of the radio. Carefully pry out the cable which is plugged into the socket on

the board. Remove the four screws and lift out the board. See Figure 1 above.

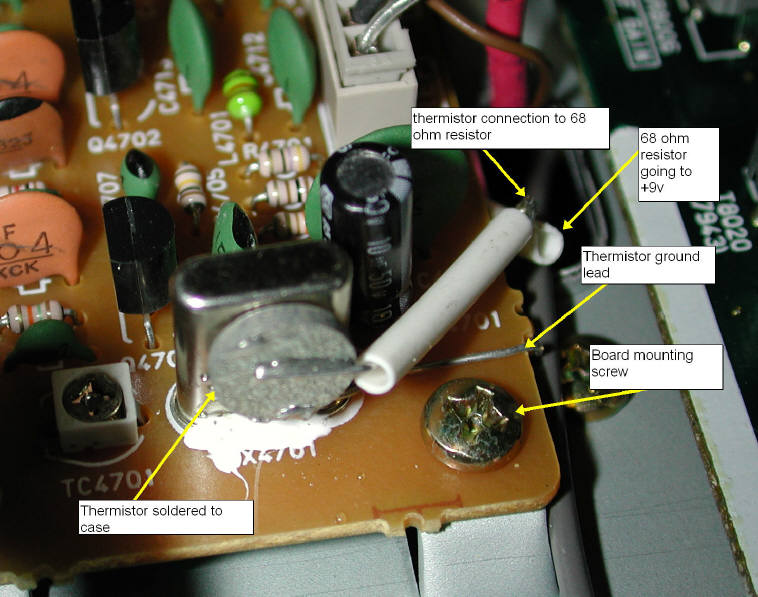

The

thermistor is connected to one side of the crystal can. To do this I used an

XACTO knife to scrape off a thin line of the surface metal of the can from side

to side near the bottom of the can. Then using a 20 watt iron I quickly heated

the can and applied solder so that I had a thin line tinned across the can. I

positioned the thermistor so that the one lead (the one going to ground) was

running along the tinned line. I heated the thermistor lead with the soldering

iron and applied a bit more solder so that the thermistor was fastened to can

by one lead. I bent the thermistor so that its body contacted the can and could

transfer heat to the crystal. The

ground lead from the thermistor was dressed across the surface of the board and

bent under the board. There it was soldered to a ground pad.

Figure

2

The

other thermistor lead (the +9v one) was cut about 3 inches from the thermistor. A 68 ohm,

¼ watt resistor was soldered to the lead and the combination bent under the

board to reach the +9 volt line on the plug socket of the REF oscillator.

Before soldering it to the 9 volt pad I pushed some insulated shrink wrap over

it to prevent shorting. See Figure 3

for the solder points.

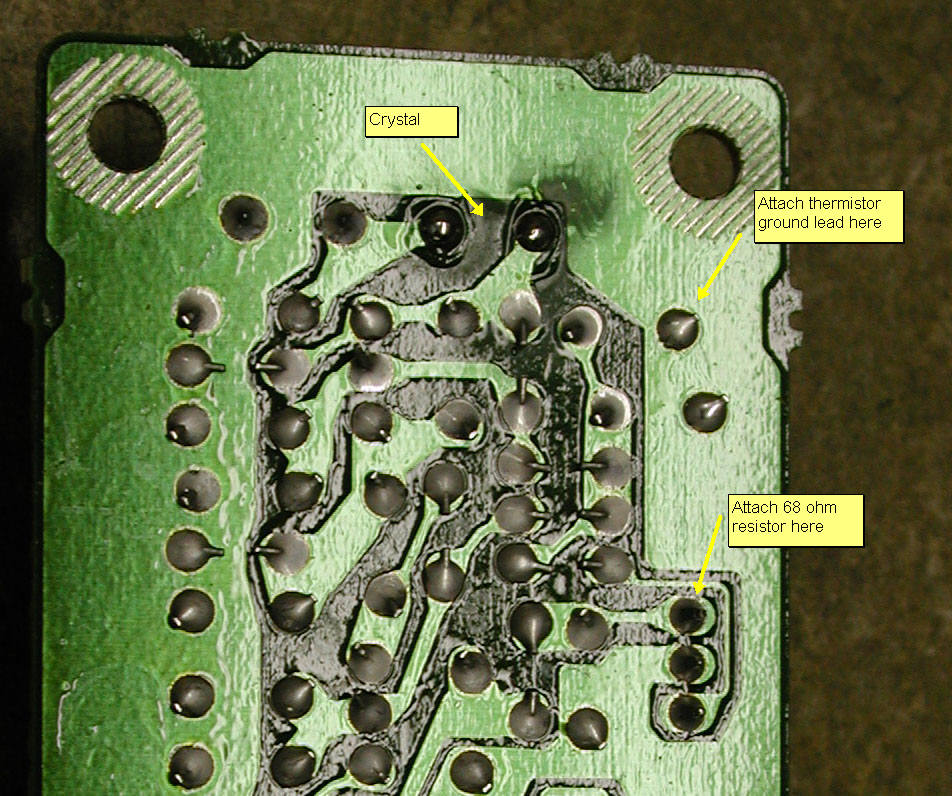

Figure

3 Location of pads for attachment of

resistor and thermistor.

After

adding the modification replace the REF oscillator board by reversing the

removal steps above. Then use the measurement and calibration method described

in “Checking

and Setting the FT1000MP REF oscillator” on my web page to adjust the oscillator to the correct frequency

and check the short and long term drift.

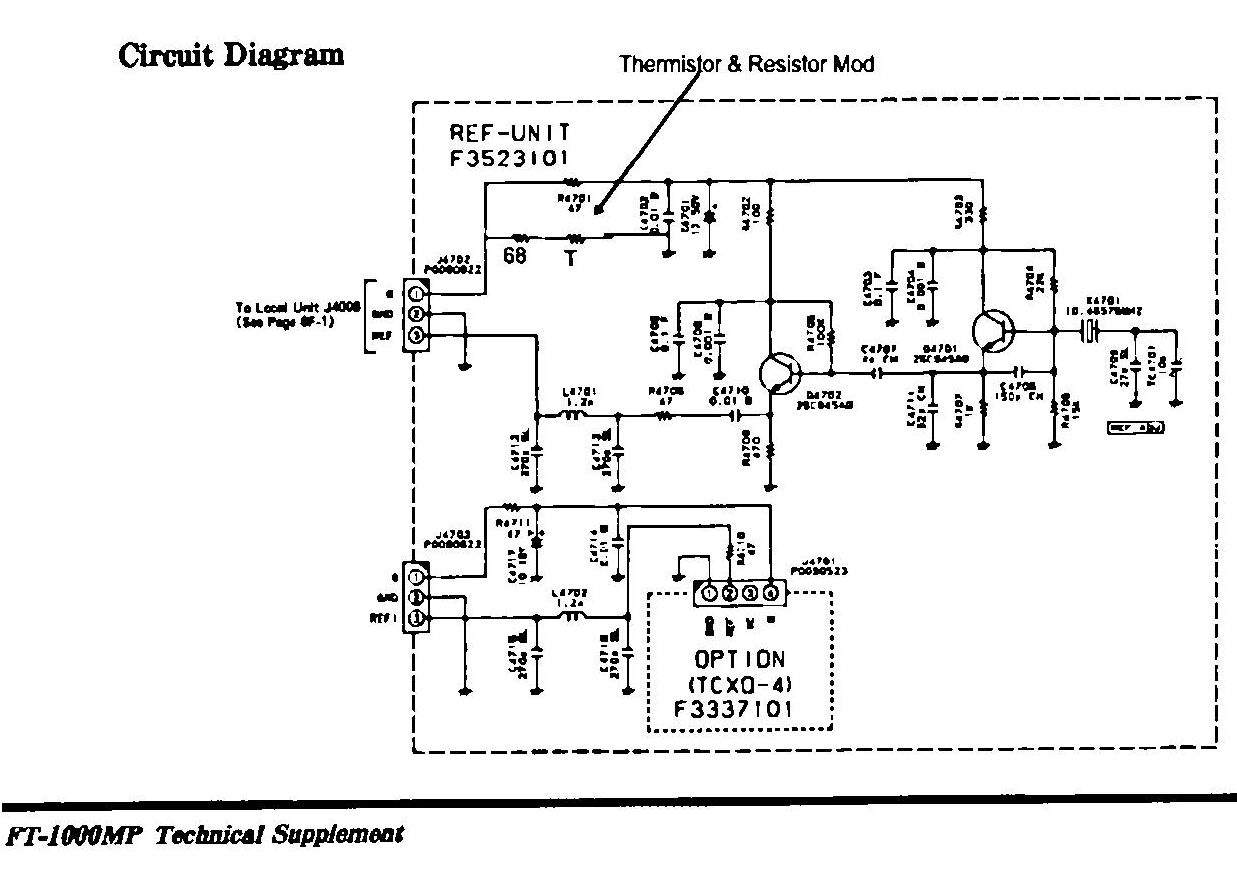

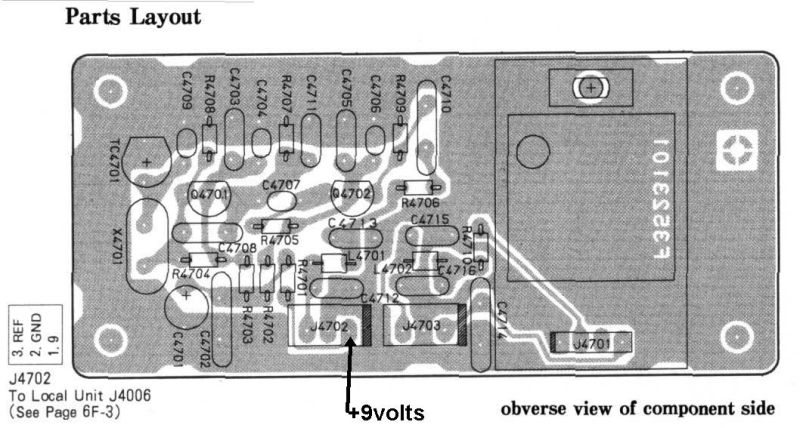

The modification gave me a short term drift such that that within two

minutes after turn on the REF oscillator was within 2Hz of the correct frequency and the long term

drift (two hours) stabilized at the desired frequency +/- ½ Hz. For a 10 MHz

oscillator this is 0.05 ppm. The schematic is shown in Figure 4 and the component layout

is shown in Figure 5 below.

Figure 4 Schematic of REF Oscillator -- shows where the thermistor and 68 ohm resistor are added.

Figure

5. Component Layout